WATER PUMP SEAL

Traction Owner’s Club › Forums › Technical › Other › WATER PUMP SEAL

- This topic has 19 replies, 4 voices, and was last updated 6 years, 7 months ago by David Selfridge.

-

AuthorPosts

-

15th April 2019 at 9:57 pm #24712

David Selfridge

ParticipantHi Guys,

I purchased a replacement water pump from Chris, (TOC Spares) after fitting it was fine, however after about 500 miles the seal has started to leak again. The coolant is being put out through the side vents of the bonnet and deposited onto the wing. Does the brass slotted nut that sits in front of the seal require a little tightening, to stop the leak or is the seal just defective. I have pumped grease via the nipple to the seal, not tested this simple fix yet. I will be surprised if this makes any difference to my problem.

16th April 2019 at 9:27 am #24714Bernie

ParticipantAs you mention the brass nut, I presume you are referring to the early type with a gland seal at the outer end of the shaft rather than the later rubber/brass/spring assembly mounted at the impeller end ……..?

The gland should be packed tightly and welllgreased – I would suggest a graphite grease if poss – and the nut tightened down to compress the packing to the point that there is some resistance so the shaft can still be turned but does not spin freely.

Thereafter, the nut will always need periodic tightening as the packing beds in and wears (the original on-board tool-kit included the spaner for that!).

It sounds to me that your assembly has now bedded in and the packing needs to be compressed a little more to be effective.

B…………….

16th April 2019 at 10:38 pm #24723David Selfridge

ParticipantHi Bernie

Thanks for your help and valuable information once again, much appreciated. The water pump is indeed the earlier type, I thought I had the complete original on-board toolkit, but the spanner for this job is definitely missing. It should be possible to make something up to do the job, any suggestions or pictures of the spanner. I will post after tightening the seal to let you know the outcome

Davy

17th April 2019 at 8:38 am #24724David Faulkner

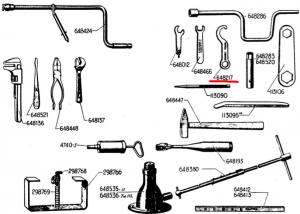

ParticipantThere is a picture of the toolkit in the parts manual in the members area David. Water pump spanner is a ‘c’ spanner part 648 217 – I have an adjustable one (somewhere) I made as an apprentice, probably too thick though for the TA pump

17th April 2019 at 6:22 pm #24729

17th April 2019 at 6:22 pm #24729David Selfridge

ParticipantMy brother works at classic motorcycles and had an adjustable “C” spanner, but unfortunately it did not work as the body is to thick and not allowing the spanner to close before it touches the opposite side of the main body of the water pump. The nut is so loose that it can be turned back and forth with two fingers, but it obviously requires the proper spanner to compress the seal.

Does anyone know where I could purchase this tool

Davy

18th April 2019 at 9:23 am #24736David Faulkner

ParticipantDavid your probably going to have to search online to find something like https://h-tune.co.uk/bc-racing-replacement-coilover-adjuster-c-spanners-3-sizes/

Then contact the supplier to find out the actual thickness as none seem to include that.

A lot are sold as ‘coilover’ spring adjusters these days, but have you any idea what the maximum thickness you can fit in is?

BTW I Googled ‘water pump C spanner’ and clicked on ‘images’ to see a lot of variants https://tinyurl.com/y2mr6hlz

- This reply was modified 6 years, 8 months ago by David Faulkner. Reason: Added link

18th April 2019 at 9:34 am #24738Bernie

ParticipantAs a(n ex-) cyclist I have a number of c-spanners for cycle applications and some of those fit this application.

In fact have only just used one to re-assemble the refurbished water pump on a friend’s 1932 C4G which, I am pretty sure, has exactly the same gland assembly as the Traction. I did then loan him the spanner until the car is running but I shall see if I can “borrow it back” and take a picture with an indication of dimensions.

B………

18th April 2019 at 10:50 am #24739David Selfridge

ParticipantThanks Bernie, that would be very helpful and extremely good of you, this has turned out to be more problematic than I first envisaged.

Kind Regards

Davy

18th April 2019 at 11:03 am #24740David Selfridge

ParticipantDave, all those pictures are more confusing, there are no dims showing thickness or even openings. The spanner my brother gave me would probably work if it was possible to get the spanner deeper, however the brass nut is almost touching the bottom of the main body of the Water Pump. This means the spanner has to be very accurate in dimension to pick up the slots in the nut before reaching the pump body on the opposite side.

Thanks for your research.

Davy

18th April 2019 at 5:47 pm #24745David Faulkner

ParticipantNo problem, maybe using Bernie’s as a pattern there should be one in the Club toolkits although how many members actually need one these days?

18th April 2019 at 10:30 pm #24746David Selfridge

ParticipantHi Dave

It would be a good idea to include in the Clubs toolkits. TOC Spare Parts sell the replacement pumps and all customers will experience the same problems as I, with the seal needing compression after the bedding in period, then a following tightening as the seal begins to wear. I have already contacted my local TOC Representative regarding this tool without success, he has loaned me tools in the past.

Davy

19th April 2019 at 9:32 am #24747Bernie

ParticipantGents,

First thing first – this is the spanner I use:

It is a simple cycle spanner – original application was the lock ring on the left hand cup of the bottom bracket.

Secondly – I personally do not believe that adding this spanner to the TOC tool kits is a particularly good solution. Those kits are intended to allow members to do what, for most people, will be a once-in-a-lifetime job and the rules state that the kit should be borrowed in its entirity and not just one odd tool at a time.

On the other hand, this spanner is a regular maintenance item – hence its inclusion in the original on-board tool kit. I would suggest anybody with this type of pump should have their own spanner and keep it in the boot because those pumps can start to weep at the most awkward times.

I think a visit to the local cycle shop will locate a suitable tool. It may need to be slightly fettled if it interferes with the pump body but then you will always have it instantly available whenever you need it.

B…………

19th April 2019 at 10:07 am #24748David Selfridge

ParticipantBernie,

Thank you very much, “WHAT” would we all do without your help and deep knowledge of the TA

Regards

Davy

19th April 2019 at 10:44 am #24749David Faulkner

ParticipantBernie how about adding the details into an edition of Floating Power then so members not reading the Forum have an idea of what they need for their leaky old style water pump?

19th April 2019 at 4:31 pm #24750Larry Lewis

ParticipantIf you don’t have the spanner, you can use a centre punch or a dull chisel and a hammer- gently tap the centre punch in the slots to tighten the nut- do it with the engine running until the leak stops. That’s what I did on my 49 Legere.

-

AuthorPosts

- You must be logged in to reply to this topic.