Wheel nut conundrum

Traction Owner’s Club › Forums › Technical › Other › Wheel nut conundrum

- This topic has 13 replies, 6 voices, and was last updated 5 years, 7 months ago by Bernie.

-

AuthorPosts

-

22nd April 2020 at 10:50 am #26496

Norman Anderson

ParticipantThis 1953 Slough Light 15 was converted to Pilote wheels at some stage of it’s life. All of the wheels were cracked, so I managed to get 5 original stove baked wheels and hubcaps from John Gillard. So far, so good. But on tightening up the wheel nuts (I wish there was a recommended torque value). I managed to strip two of them. (Thank God the studs look ok).

on checking the TOC spares listing, I see there are special nuts for Pilote wheels and nuts for Slough wheels. Am I therefore, trying to use the wrong nuts for these wheels? Thanks.

22nd April 2020 at 12:59 pm #26498

22nd April 2020 at 12:59 pm #26498Bernie

ParticipantNorman,

Probably not.

Both Slough rims and Pilote rims require the same profile wheel nut. Originally those nuts were brass – presumably to be sacrificial and prevent the hub studs being stripped or broken if overtightened.

The trouble is most originals are now so worn that even if they appear to be tight they are probably not. I have a bucket with about 50 of them which are only good for the scrap value of the material.

When I fitted my Pilotes I managed to obtain a set of (steel) Renault 16 wheel nuts from a friendly Renault enthusiast. They are perfect but, sadly, also in short supply today.

However, there are a number of companies supplying suitable steel wheel nuts with the correct thread and shoulder and that is what I recommend.

B……

22nd April 2020 at 6:49 pm #26499Patrick Russell-Jones

ParticipantHi Norman

I have these fitted on my Lt15 https://www.ebay.co.uk/itm/17mm-Shallow-open-ended-wheel-nuts-Chrome-M12-x-1-25-Nissan-etc/193339226476?hash=item2d03ea796c:g:SusAAOSw~QVeQT3j

Patrick

22nd April 2020 at 7:20 pm #26500Norman Anderson

ParticipantBernie, thanks for your advice. Got the spec of the Renault 16 website, but they were still v expensive. Scoured the internet until Patrick’s advice came through. 1£ per nut. Job done! Thanks again. Norman

23rd April 2020 at 4:23 pm #26501

23rd April 2020 at 4:23 pm #26501Philippe Allison

ParticipantThese are the correct nuts for the Pilote wheels. I have them on both my cars.

All the best Philippe

26th April 2020 at 11:31 pm #26517Roger Grix

ParticipantThe instructions for skimming the brake drums are:

Fix the hub and drum assembly, placing a washer 4mm. thick on each stud and locking with the wheel nuts tightened to a tension (torque) of 5mkg. (36 foot pounds).

This is to ensure that drum and hub are tightened together as they will be when the wheels are fitted to the car, thus ensuring that the drums will be circular when the wheels are torqued. The 4mm washer is in place of the wheel rim. The logical inference is that the wheel nuts should be torqued to 5mkg (36 ft lbs) when in service.

I have a feeling that I have seen a whole list of torque settings somewhere but can’t remember where. I will have to think.

I hope this helps,

Roger

10th May 2020 at 7:24 pm #26632Roger Grix

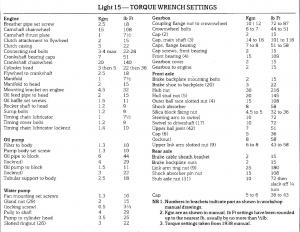

ParticipantI have found the list of torques.

Unfortunately w still can’t upload .pdf to the forum.

However the document is in the archives. If you use the TOC index tool and enter “torque settings” you will find a link to Volume 16 (1991-92) Issue 1 (March).

There are most of the figures that you may want (but not the wheel nuts).

If you have a problem, PM me an email address and I will send you the .pdf

Roger

10th May 2020 at 7:29 pm #26633Roger Grix

ParticipantA caveat – These were taken from the 1938 manual so may not still be valid.

Roger

11th May 2020 at 9:02 am #26637David Faulkner

ParticipantRoger I cropped the pdf just to show the Torque part and converted to a jpg so it can be posted as an image file:

11th May 2020 at 10:12 am #26638

11th May 2020 at 10:12 am #26638Roger Grix

ParticipantThanks David.

11th May 2020 at 11:52 am #26640Bernie

ParticipantJust to add to the lack of precise information on this subject ……

The workshop manual refers to fitting wheels in a couple of sections. In each case the instruction is simply “Fit wheels” in the instruction section and, in the tool column, it only states “Wheelbrace”.

When using a wheelbrace one has no means of checking the applied load so, on that basis, I would conclude no precise torque was actually specified for the wheelnuts. That is an assumption and I shall be very happy to be proved wrong.

<p style=”text-align: left;”>B…</p>11th May 2020 at 12:16 pm #26641Roger Grix

ParticipantAs I indicated above, the instructions for skimming the brake drums require the studs to be torqued to 5 mkg (36 lbs.ft).

I think that this can be assumed to be the operational wheel nut torque as, presumably, the intention is to simulate the “bolted up” condition, duplicating any distortion of the drum when the wheel is fitted.

Roger

12th May 2020 at 7:47 am #26645Norman Anderson

ParticipantThanks Roger, Bernie and David,

On the subject of torque – the engine has been overhauled. Presumably the head needs to be retorqued. When is the best time to do this? After say 300 miles? Hope I can do this without removing the bonnet.

I see Oldtimer Werkstatt writes this on the subject (he seems to redo the head torque after the first warm cycle) The 11B was picked up by the owner – after a test drive – on Saturday.

Before that I had tightened the cylinder head screws – twice, after warming up, in total over 1 turn! The aspest free gasket gives way much more than the former material. After about 250 to 300 km the customer should come by again to tighten the screws again.12th May 2020 at 8:35 am #26646Bernie

ParticipantNorman,

I normally re-torque a head after an initial warm up and then again around the 500 mile mark – both on a hot engine.

To get an accurate torque you need to eliminate any “stiction” which will cause a false (high) initial torque reading. So, before re-torquing each fixing, slacken it off enough to turn freely (about a quarter turn is usually adequate) and then, in a single sweep, immediately re-tighten to the correct torque (5mkg?).

The job is possible without removing the bonnet but access will be restricted and that might affect your ability to re-tighten some of the fixings in a single move.

B…….

-

AuthorPosts

- You must be logged in to reply to this topic.