Gear lock mechanism and clutch adjustment

Traction Owner’s Club › Forums › Technical › Gearbox & drive shafts › Gear lock mechanism and clutch adjustment

- This topic has 4 replies, 3 voices, and was last updated 3 months, 4 weeks ago by Bernie.

-

AuthorPosts

-

31st August 2025 at 2:07 pm #37435

Jakub Salata

ParticipantHello,

in the car I recently started working on (1938 11BL) gear engagement requires quite a bit of force on the lever, making it difficult to change gears smoothly – typically crashing into reverse coming out of 1st, or too quick changes between 2nd and 3rd gear (not enough time for the synchros to engage properly).

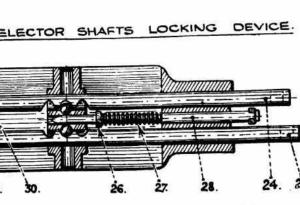

Today I looked into adjusting the gear lock mechanism, only to find none of it where it was expected…

Is it safe to assume someone swapped at least the upper cover from a DS gearbox? Is there any way to tell between a 11CV and DS gearbox just by looking at one? Why on earth would someone do this?

Also, the clutch engagement point is very high, at the end of pedal stroke. I looked into adjusting the cable, but both side adjusters are as slack as they can be. It looks like I’ll have to drop the gearbox to inspect clutch for wear and at the very least set the toggles correctly?

4th September 2025 at 11:25 pm #37457Chris

ParticipantWhen I first got my 51 Normale it did not have the interlock fitted. Whoever had last taken the top off it had just left all the bits out.

I haven’t tried to compare them but I would be surprised if a DS cover would fit a Traction box.

I cant quite get my head around the biting point being high and the cable being slack. If the cable is slack it should mean the biting point would be near the bottom (fully depressed) end of the pedal’s travel. That would mean your clutch might not be disengaging which would make changing gear difficult.

If the interlock balls are still in the top cover, but the operating rod is not there to move them, that would also make it hard to move the lever.

Chris

5th September 2025 at 3:10 pm #37459Jakub Salata

Participant<p style=”text-align: left;”>If someone adjusted the clutch toggles wrong (too high) when installing one, there might not be enough space for proper throwout bearing clearance and position adjustment.</p>

If the gear lock mechanism was removed, the 2 balls wouldn’t really cause much resistance, and might fall out of the T piece hole, and I couldn’t find one at all (though access is terrible).If it was disconnected and in place, the selectors wouldn’t move at all.

Is there any Citroen model which might have a very similar gearbox but without the lock mechanism?

16th October 2025 at 2:50 pm #37603

16th October 2025 at 2:50 pm #37603Jakub Salata

ParticipantI have solved at least part of the mystery. Car was first registered in January 1938, the last month before the clutch lockout mechanism was introduced. Must have beeen a solution to the heavy and clunky shifting. I will be fitting a later model upgraded cover with the lockout, the godawful way the shifter works now is not worth the originality.

I need to inspect the clutch anyway, everywhere I’ve checked it is suggested to drain the gearbox oil, and split it along the diff centerline for removal, is that really necessary? Can’t it just come off intact, together with the bellhousing?

Also, is it easier to remove the gearbox from a supported engine, or the whole assembly and separate it later? I have a 500kg capable hoist, so weight is not an issue here.

- This reply was modified 4 months, 1 week ago by Jakub Salata.

29th October 2025 at 7:10 pm #37617Bernie

ParticipantDo NOT split the box from the bell housing to work on the clutch.

It is fiddly possible – but not easy – to remove gearbox/bell housing assembly from a Légère without removing the engine as well.

You will need to disconnect the throttle linkage to the carb and remove the rear engine mounting and battery to enable the front of the engine to be raised to achieve the necessary clearance at the cradle.

In my experience, if you have the facilty to remove the engine and gearbox as an assembly and then separate them, that is the best approach.

B…..

-

AuthorPosts

- You must be logged in to reply to this topic.